Your cart is currently empty!

Why Should We Use a Soil Monitoring System?

The purpose of weather stations used in PV projects is to measure the efficiency of the plants. When the efficiency obtained from the panels decreases, it is understood that this is due to some factors. The most important factor is the soiling of the panels as. Soiling on the panels adversely affects the efficiency of the generated electricity.

Due to the soiling of the surfaces of the PV panels, serious losses may occur due to the decrease in the amount of solar irradiance reaching the panels. Therefore, soiling stands out as an important parameter to be considered in solar energy systems. The only thing that needs to be done against soiling is to clean the panels. However, this process is costly in large PV plants, especially in water-lack areas.

Not knowing the amount of soiling creates uncertainty about the extent of the production loss due to soiling without any sensor. For this reason, Seven has developed the Soil Monitoring System. Thanks to the soiling sensor, the soiling ratio and power loss in the facility can be observed and this loss can be prevented by cleaning the panels when it reaches the set limit. With this system developed by SEVEN Sensor, the value of the amount of soiling is calculated as follows.

![]()

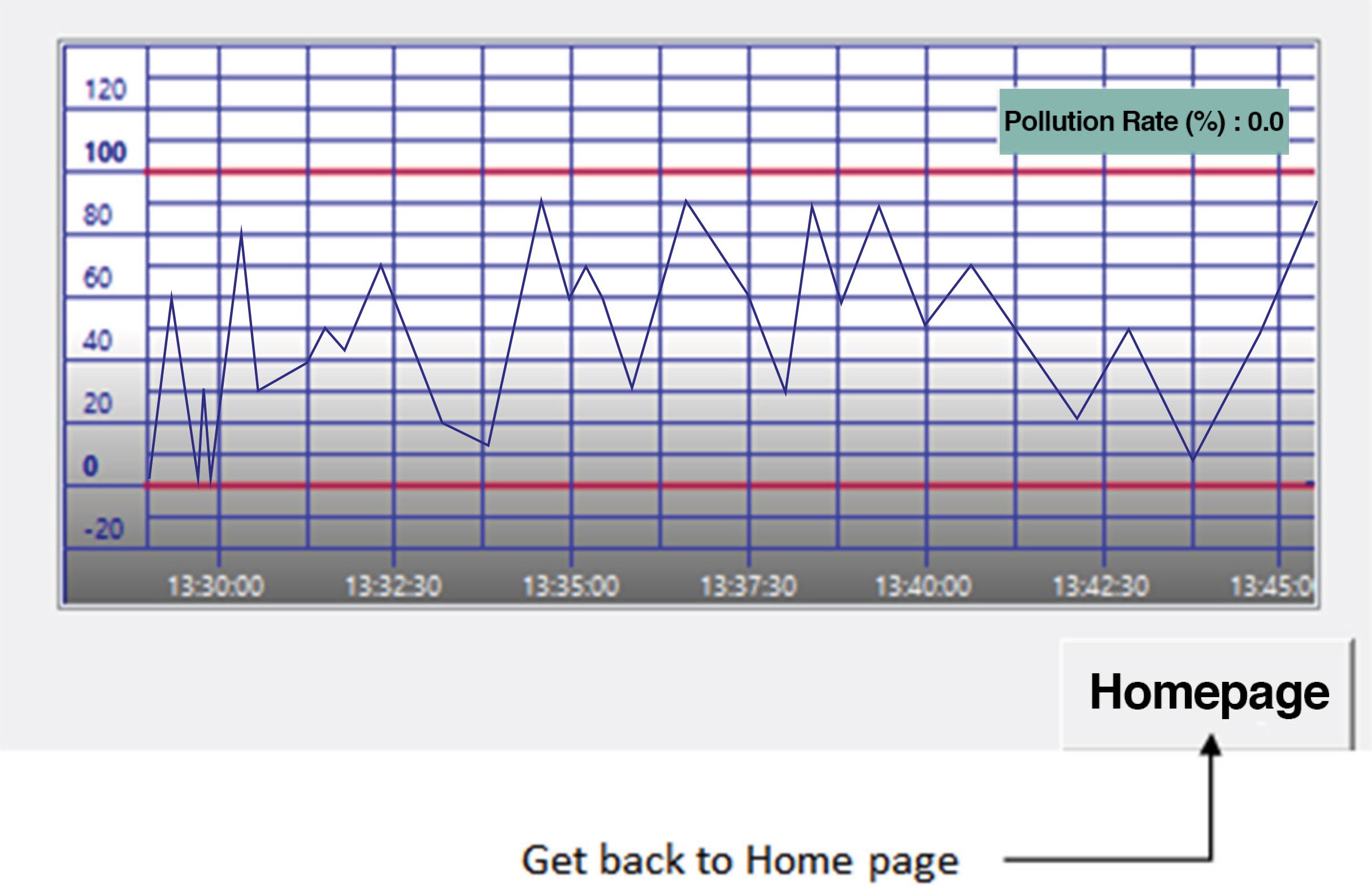

With this product developed by Seven, the amount of soiling can be monitored as a percentage (%) in PV projects. Thanks to the software programmed according to the demand of the end-user, system is activated once the soiling ratio reaches the set level. As an example, if the end-user wants to receive a warning and clean the panels when the soil on the panel exceeds 2%, the program is written accordingly and the warning system is activated them. As soon as the soiling ratio exceeds 2%, a warning is received via the system. This ratio can be increased or decreased according to the requirements of the end-user.

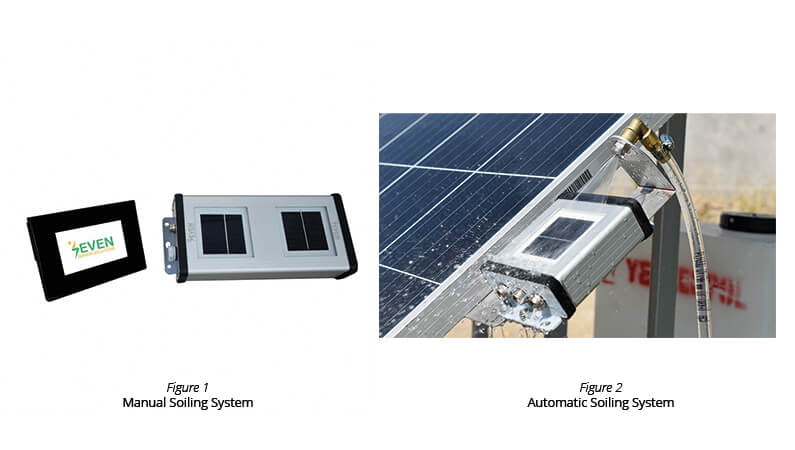

SEVEN manufactures two different soil monitoring systems, manual and automatic. Soil Monitoring System; It is a combined system, consisting of two SEVEN irradiance sensors, which can be cleaned manually or automatically, and an HMI programmable logic controller(PLC). The Automatic Soil Monitoring System is cleaned directly with water. In this system, there is no need for an employee to go near the sensor and clean it manually. Especially in roof top projects, it is both time-consuming and dangerous to go to the roof and manually clean one of the sensors. For this reason, it is recommended to use an automatic soiling sensor, especially in roof top projects. Manual Soil Monitoring System; It is used to measure the soiling ratio between the two sensors by cleaning one of the sensors daily and the other will be cleaned at the same time as the PV panels.

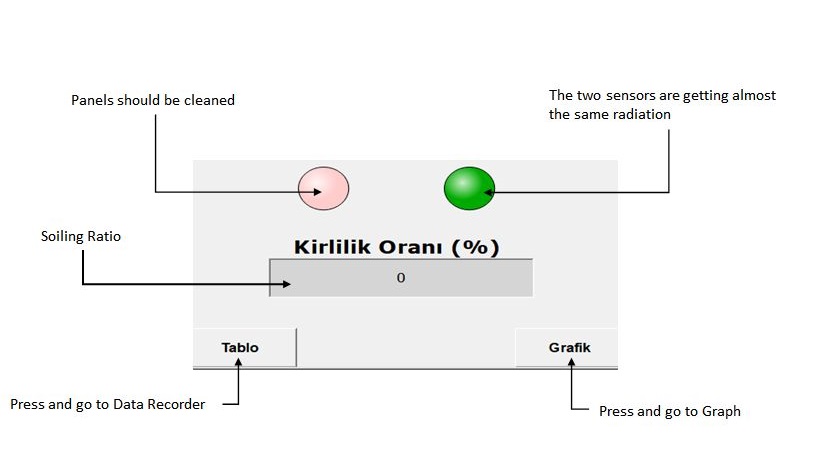

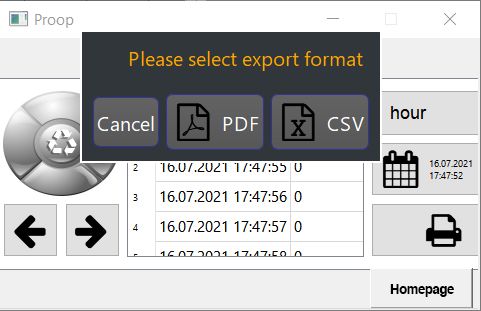

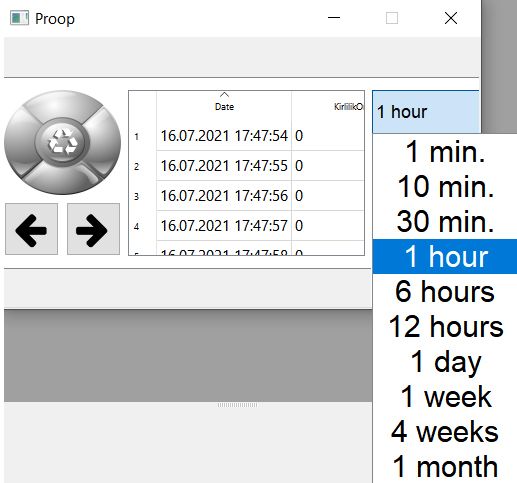

The PLC and the two sensors are communicating via Modbus RTU Protocol. The two irradiance sensors receive solar radiation, the power per unit area, from the sun and measure it in Watts per square meter. Afterward, the difference between the data obtained from the two sensors is measured and transferred to the PLC, which will give the average Soiling ratio for each hour daily or hourly and the soiling rate (%) is displayed on the screen. If the difference between the two sensors is greater than the percentage specified by the customer, the Red LED will light up to warn the user to clean the panels. Otherwise, the Green LED lights up. This screen allows the end-user to retrieve all the data recorded during the measurement, either in PDF or Excel format. Data can be taken at 1 hour, 6 hours, or more according to your preference.

The soil monitoring system is tested before delivery. The two Irradiance sensors are calibrated under natural sunlight or by sun simulator and compared with a calibrated reference cell at Fraunhofer-institut für Solare Energie systeme ISE, Germany. As per the IEC 61724-1 the Soiling Ratio Calibration should be repeated at least annually.

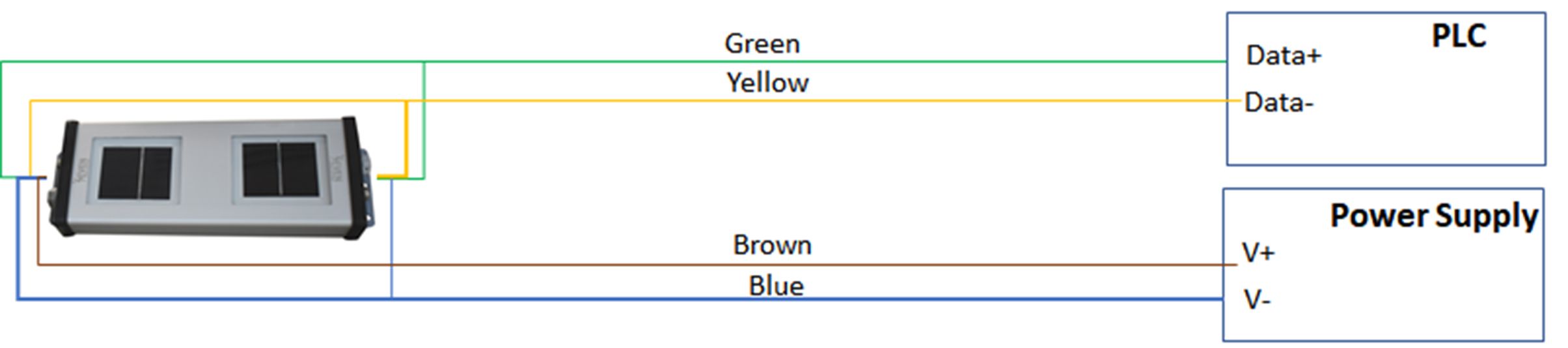

The communication between the two irradiance sensors and the PLC is done through a Modbus RTU protocol, so that the data collected goes directly from the sensors to the PLC.

The diagram below explains how to install the soil monitoring system:

As Seven, we produce sensors for which you can evaluate performance so that all fields have higher energy efficiency than before, by responding to your request for all kinds of sensors you may need for solar power plants in a timely manner. For more detailed information, you can review our products and page, if you have any questions, you can contact us.