Your cart is currently empty!

What is the importance of temperature in SPPs? What does Seven Sensor promise?

The sun is an unlimited natural energy source. Human beings who want to benefit from this natural energy source have invented photovoltaic solar panels under the roof of clean energy. Photovoltaic solar panels constitute a very large part of the investment value of solar power plants today. In order to get a healthy return on this investment, it is necessary to provide some data follow-up in a healthy and accurate way. One of the most important of these data is the temperature of the panels.

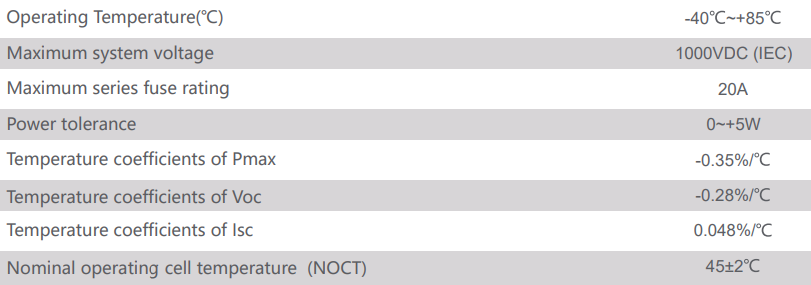

During the production process of photovoltaic solar panels, many safety and performance tests are applied by the relevant laboratories. Solar panels are tested in environments with an ideal temperature of 25 degrees celsius and 1,000 W/m2 solar radiation. According to this environment, the efficiency of the tested panels and the effects they show are calculated. While some of the energy received from the sun is converted into electrical energy, some of it emerges as heat energy. As the panels heat up, the current (I) value increases while the voltage (V) value decreases. With the decrease in voltage value, there is a decrease in output power and this causes data loss.

This situation can be most easily explained as follows; You have a 370 Watt monocrystalline panel with the above specifications. And your panel temperature is measured at 45 degrees. So what is your data loss according to temperature?

Panel Output Power x (1- (Panel Temperature- 25) x Pm)

370 x (1- (45-25) x 0.0035) = 344.1 W, our output power will be lower and efficiency will decrease.

“Well, if this panel temperature is so important, how do I measure it?” we seem to hear you say. Here, as Seven Sensor, we state that we are with you and offer you our sensor solutions. You can use our Module Temperature Sensor models with the solutions we offer you in order to ensure the temperature monitoring of your panels.

Our Module Temperature Sensors have two different communications, Modbus and Analog. Our Module Temperature Sensor measures the temperature of photovoltaic solar panels in degrees celsius (°C) using a PT1000 probe. The PT1000 probe used to measure the panel temperature is mounted inside the EVA coating between two layers. This allows for a more accurate measurement as it has the same heat transfer properties as the panel backing material as specified in the IEC 61724 standard. The measurement range of our sensors is between -40°C and +85°C.

Our models are simply as follows;

Module Temperature Sensor- PT1000

This Module Temperature Sensor is compatible with SEVEN Irradiance Sensor Box. Thus, you can both monitor the performance ratio by receiving irradiance data and monitor the temperature of your panels. Module Temperature Sensor is sent to the end user with a 3 meter communication cable.

Module Temperature Sensor- PT1000 Modbus

The communication of our Modbus Module Temperature Sensor is provided by Modbus RTU transducer via Modbus RTU Protocol. This sensor can communicate with dataloggers and PLCs with Modbus RS485 communication protocol. Module Temperature Sensor is sent to the end user with a 3 meter communication cable.

Module Temperature Sensor- PT1000 Analog 4-20mA & PT1000 Analog 0-10V

The Analog Module Temperature Sensor is compatible with datalogger, gateway and PLCs with 4-20 mA input port and 0-10V input port.

You can review our website for your needs and expectations. You can reach our Sales Department by calling +90 554 116 00 19 for product supply and quotation, and our Technical Support Department by calling +90 553 892 26 70 and +90 501 102 88 70 for technical information and support.