Soiling from dust, sand, pollen, salt, and other particulates reduces the performance of PV panels over time, leading to power output losses. The panels must be cleaned—but which panels, and how often? In solar power plants, not all panels soil at the same rate. Not all experience the same conditions, topographies, or weather patterns.

That’s where soiling stations come in. A soiling station, or soiling sensor, is used to help operators determine when and where panels need cleaning. It is a way of assisting PV plant operators and quantifying power loss.

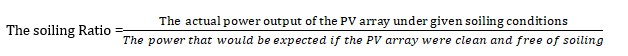

The soiling monitoring system doesn’t provide a physical measurement of the dust and particulates on the actual panels. Rather, it’s used as a reference point to understand what percentage of power loss is due to soiling. It provides a representative value that’s meant to define a region of soiling and give that approximation.

Typically, soiling is monitored on a utility-scale and commercial and industrial solar PV plants. There are many factors that go into the decision to monitor soiling or not, such as site location, the rate of soiling, local weather patterns, and cleaning costs.

Rainfall measurements may be used to estimate the cleanliness of modules. However, if the soiling ratio is measured, the module cleanliness is directly known. So, if you have a soiling sensor you don’t need to use a rainfall sensor.

The IEC 61724-1 Class A standard includes a soiling standard, with recommendations for the number of sensors and so forth. In order for a solar PV plant to achieve Class A status for IEC, there must be a soiling system onsite per those recommendations. Seven Soiling Monitoring Systems, also meet these requirements.

Benefits & Advantages of Soiling Sensor in Solar Plants

SEVEN manufactures two different soil monitoring systems, manual and automatic. Manuel Soil Monitoring System (Traditional two PV Cell systems) monitors using a clean and a dirty PV cell. They compare the power output of the panels to calculate the soiling ratio and transmission loss. They require two cells because they must have one clean and one dirty in order to get the transmission loss measurement. it’s generally accepted that the traditional two-cell systems are an accurate method for calculating transmission loss. They have a large surface to collect dust and that reduces spatial variability.

The Automatic Soil Monitoring System is cleaned directly with water. In this system, there is no need for an employee to go near the sensor and clean it manually. Especially in rooftop projects, it is both time-consuming and dangerous to go to the roof and manually clean one of the sensors. For this reason, it is recommended to use an automatic soiling sensor, especially in rooftop projects.

You can also use the soiling data to forecast trends over time, in order to proactively create cleaning schedules that make sense for your plant rather than scheduling less efficient, routine cleaning two or three times a year. You can factor in weather patterns—knowing what times of year tend to have more pollen, for example, or when you can forecast big storms that clean the panels naturally.

Monitoring the trend of soiling over time with the trend of power loss over time helps to more quickly identify and troubleshoot the source of a power loss.

For example, if your soiling sensor reads 3% soiling but you’re experiencing a 3.4% power loss, you can see if the trend matches. Perhaps you have little rain events and things of that nature, and you see spikes and a steady decrease at the same rates. You can deduce that the actual power loss is 3.4%, and it’s all due to soiling.