PV solar installation in India

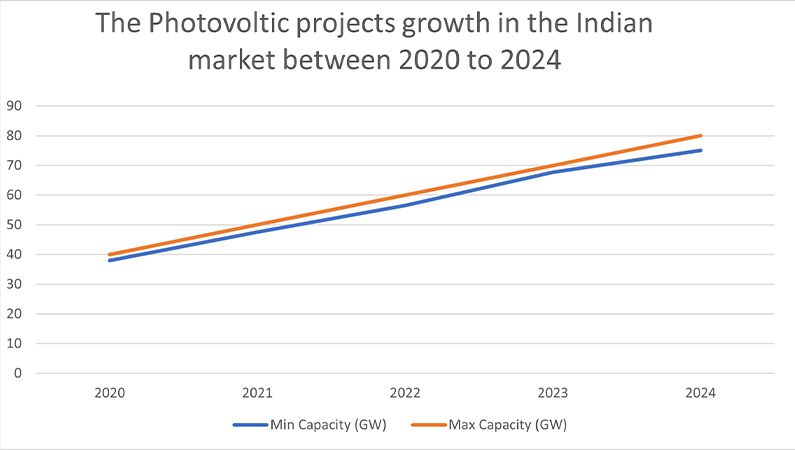

As photovoltaic solar energy continues to expand as a sustainable power source worldwide, the India market is affected by this growth, with a growth rate of 97% to 100% between 2020 and 2024. As illustrated in the below sketch. India’s installed PV capacity is expected to hit 104 GW by March 2025, as per the PV magazine Energy Store.

A graph illustrates the growth of the PV industry in India.

The integration of solar weather stations into photovoltaic (PV) systems has become increasingly essential. The weather station includes sensors that are monitoring the meteorological parameters which directly impact the performance and efficiency of the photovoltaic (PV) system. In this article, we will be exposed to the Indian market, and will recommend the sensors that need to be included in the weather station that align with the Indian climate.

What are the general aspects of the Indian climate?

India’s climate is defined by a wide range of weather conditions due to its vast geographic scale and varied topography. In summer, temperatures can exceed 40 °C (104°F), while humidity levels vary significantly from 15% in dry areas to 98% in more humid regions. Additionally, the dust levels are high to elevated due to dry conditions. Rainfall also fluctuates across different seasons. To effectively monitor these diverse conditions, the following sensors are recommended:

- Solar Irradiation Sensors

- Ambient Temperature Sensors

- Module Temperature Sensors

- Wind Speed and direction sensors

- Soiling Sensor

- Humidity Sensor

- Rain Gauge Sensor

- Barometric Pressure Sensor

Monitoring of the above parameters is necessary to operate PV plants at their maximum power production level. The performance of a PV plant can be calculated only if there is an irradiance sensor in the plant. Other sensors also guide plant operators to understand and evaluate the changes in the production of the plants. Usually, plants operating under %80 performance are considered to have insufficient power production, and an investigation is required to understand the reason for that drop. If there is no sensor in the plant, the operator cannot notice that drop, and we cannot evaluate the reason for the drop.

It is worthy to mention our soiling sensor that is our best seller in the India market due to the prevalent dust condition in India. These dust effects on the PV system efficiency need to be monitored, and the optimal time to clean the PV panels needs to be determined according to the soiling ratio that will be calculated through our soiling sensor as indicated at the IEC 61724-1 annex C.

Seven Sensor Solution’s Automatic soiling sensor.

Our sales team will be happy to answer all of your questions at: sales@sevensensor.com