Your cart is currently empty!

Irradiance Sensor With Modbus RTU Output

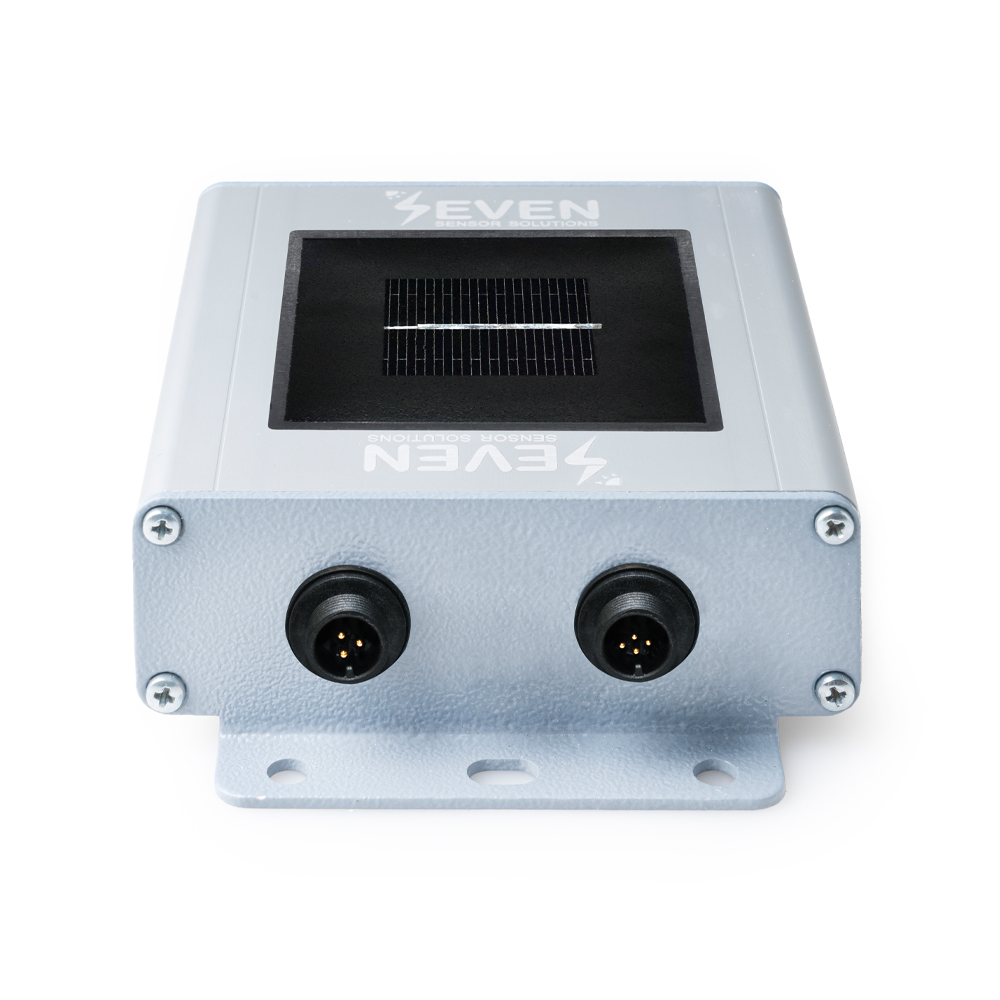

It's a Sensor Box for Solar PV Plants having a Modbus RTU Output. Besides Irradiance Sensor, it includes also an Internal Cell Temperature Sensor.It is compatible with all Modbus RTU Dataloggers. It is supplied along with Mounting Bracket and Cable.

WORKING PRINCIPLES

Solar irradiance is the power per unit area received from the sun and measured by the PV pyranometer, i.e. the irradiance sensor, as electromagnetic radiation in Watt per square meter (W/m²).

This sensor consists of a solar cell made of monocrystalline silicon, which is activated by light and produces an electric current that is converted into millivolts (mV) thanks to the connected shunt resistor on its back side. A temperature sensor is located at the back of the cell to measure the temperature of the cell which causes a small deflection of the current. The temperature increases in inverse proportion to the current production of the cell. The monocrystalline cell and the temperature sensor are connected to an electronic card, which is designed to calculate the temperature compensated solar irradiance value in W/m². Thanks to the design of this card, it is possible to connect up to 7 different sensors and provides an RS485 port for data transfer in Modbus RTU protocol. SEVEN provides SunSpec compliance for the necessary devices, too.

CONSTRUCTION FEATURES

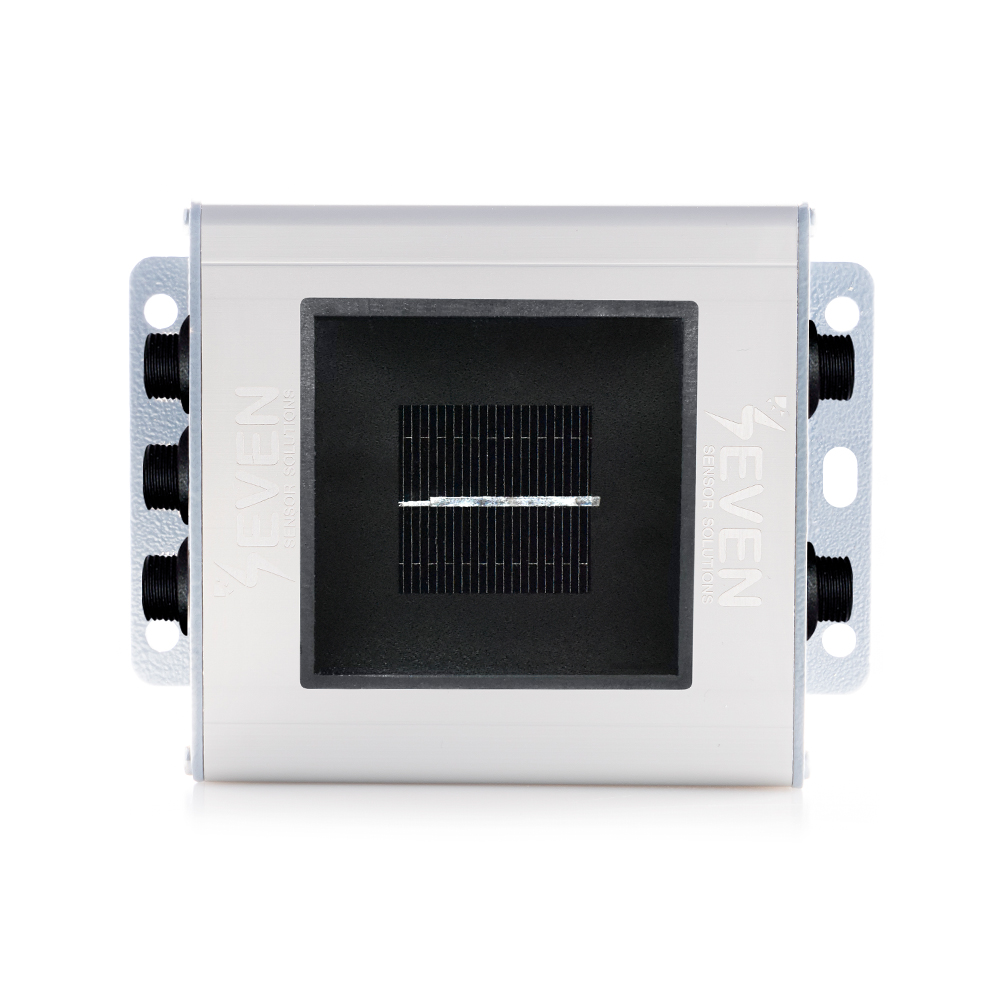

Monocrystalline Cell: The cell is laminated with 2 EVA sheets, one Tedlar sheet and 3mm tempered glass under 180 °C homogeneous temperature and under vacuum effect. The size of the monocrystalline cell is 52×52 mm² or 31x31mm².

Sensor Box: It is an UV protected aluminum box. The sensor box has two opening access and the mounting holes on its sides are for easy site installation. There are three options for IP Class; IP54, IP65 and IP68. For ventilation purpose, there are 1mm holes at bottom side of the box, or a ventilation plug on its side.

Connectors: Each plastic connector which is UV protected has a different pin number which prevents any connection confusion during site installation. The connection cables are delivered as 1,5m or 3m lengths. SEVEN irradiance sensor is designed as plug & run device and end user friendly operation.

TECHNICAL DATA

| Item Code | 3S-IS |

| Reference Cell | Monocrystalline Silicon (31 mm x 31 mm) |

| Current Shunt | High precision shunt resistor directly soldered to the terminals of the cell |

| Irradiance Range | 0 – 1600 W/m² |

| Uncertainty | ≤1,2%, as per IEC61724-1 standard Class A |

| Resolution | 0.1 W/m² ≤ 1W/m² as per IEC61724-1 standard Class A |

| Response Time | 1 sec. less than 3 sec; as per IEC61724-1 standard Class A |

| Drift | Very small drift of <0.3%/ year |

| Field of View | Larger than 160° as per IEC61724-1 standard Class A |

| Tilt-Azimuthal Angle | 0°- 0° , ≤ 1°; as per IEC61724-1 standard Class A |

| Output Rate | 1/s |

| Data Output | RS485 up to 38400 Baud |

| Communication Protocol | Modbus RTU |

| Power Supply | 12 to 30 V DC |

| Power Consumption | 30 mA max @24 VDC |

| Electrical Connection | 3 m LIYYC11Y PUR Cable, UV and Weather Resistant |

| Galvanic Isolation | 1000 V between power supply and RS485 bus |

| Cell Temperature Sensor Type | PT1000 Class A as per EN 60751 |

| Operating Temperature Range | -40°C to +85°C |

| Operating Humidity Range | 0 to 100 % |

| Box Dimensions | 140 mm x 110 mm x 42 mm (W x L x H) |

| Weight | 0.3 kg |

| IP Rating | IP54 (IP65, IP68 options) |

| Sensor Housing Material | Aluminum |

| Compliant Standard | IEC 61724-1:2021 and IEC 60904 |

| Calibration | Each sensor is calibrated under Class AAA Sun Simulator as per IEC 60904-2 and IEC 60904-4 by using a reference cell calibrated by ISFH-Germany |

| Test | The test is carried under natural sunlight by using a calibrated reference cell from Fraunhofer ISE, Germany |

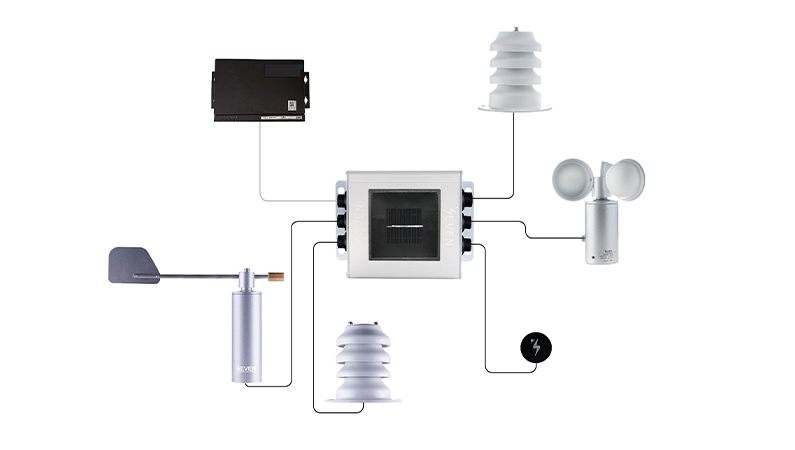

WIRING EXTERNAL SENSORS

Details of SEVEN Irradiance sensor

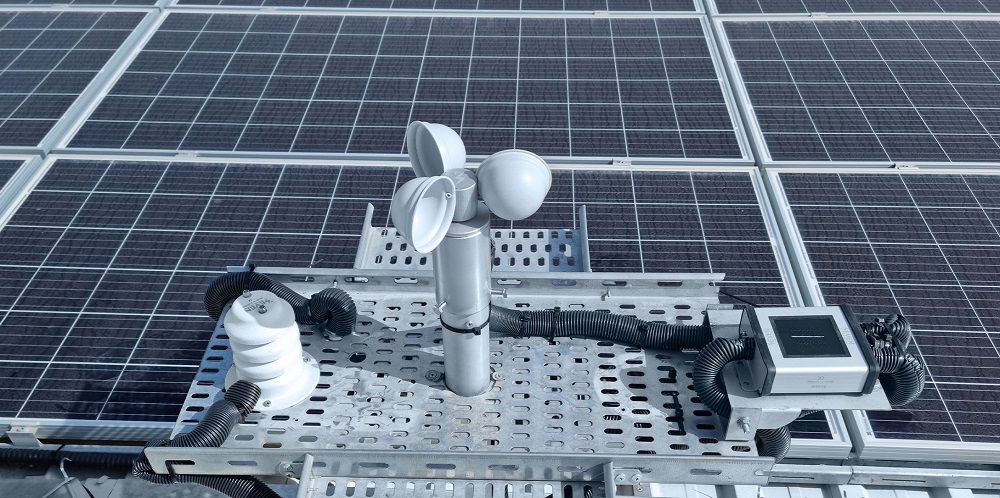

The irradiance sensor or PV pyranometer is a photovoltaic sensor used to measure the amount of solar energy in natural light and is particularly used in meteorology. It measures the power of total solar radiation in watts per square meter (W/m²).

The solar irradiance sensor is a simple economical solution to monitor the performance of the solar system at any time. Entirely manufactured as a cell for the PV system and equipped with a temperature compensation system, the irradiance sensor measures precisely and reliably the energy expected to be produced by the system. You will thus be able to benefit from the best performance for your solar panels.

Irradiance sensor with Modbus RTU Connection

In terms of connection or communication with other sensors and dataloggers. Several types of irradiance sensors are available with different output signals such as the irradiance sensor with Modbus RTU output and the irradiance sensor with analog output. In this text, we will focus on irradiance sensors with Modbus RTU output.

First of all, Modbus is a serial communication protocol widely used by industrial electronic devices. In Modbus, the connection is established between a master (host) and slaves (devices connected to COM ports). The Modbus allows access to the configuration of the peripherals and to read measurements.

The irradiance sensor with Modbus RTU output is an advanced, weatherproof junction box made of UV-resistant materials. It is constructed from a monocrystalline solar cell connected to a high-precision shunt. It contains a Modbus output which is used to deliver the measurements obtained by the sensor to the datalogger via a RS485 cable. This type of Modbus irradiance sensors also has up to five input ports that allow the communication with five external sensors as following; Module Temperature Sensor, Ambient Temperature Sensor, Wind Speed Sensor, Wind Direction Sensor and Relative Humidity Sensor.

Irradiance sensor’s components

An irradiance sensor consists essentially of 3 main parts: Protective box, Photovoltaic cell, Electronic card.

The photovoltaic cell, which has a monocrystalline silicon structure, is the part that absorbs solar radiation. It has the same characteristics as a photovoltaic panel cell. Therefore, it behaves in the same way as the panel under the effect of light and heat. Then, with the help of a microprocessor, the electronic card gets the ability to collect the processed data.